Current position:

Home >

Products >

Homogenization and emulsification >

Electric lifting emulsifying machine >

Electric lifting Emulsifier

Current position:

Home >

Products >

Homogenization and emulsification >

Electric lifting emulsifying machine >

Electric lifting Emulsifier

Feel free to call us for more information

400-808-1508

Products

Products

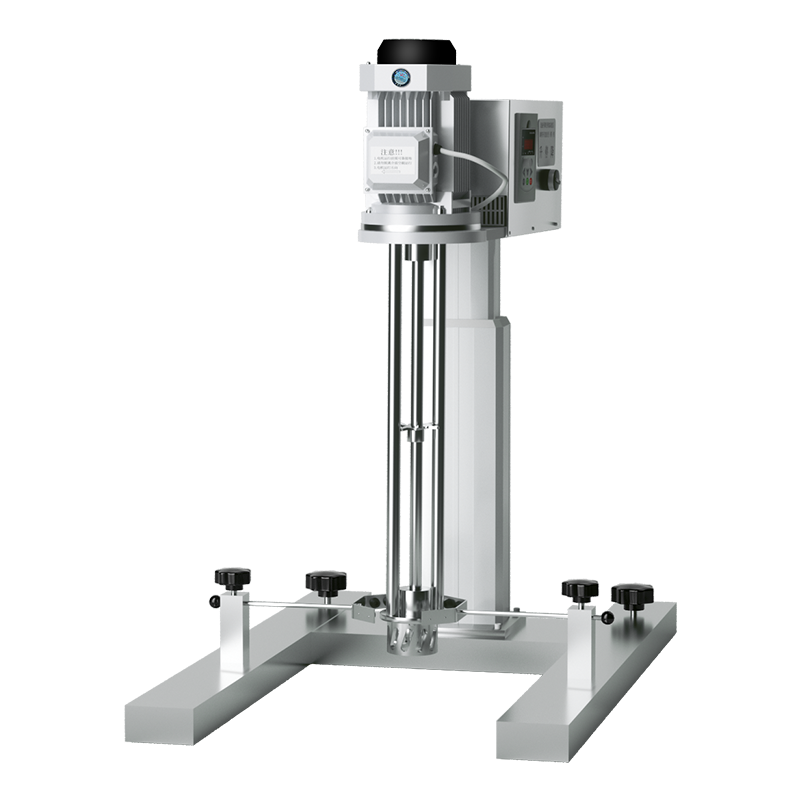

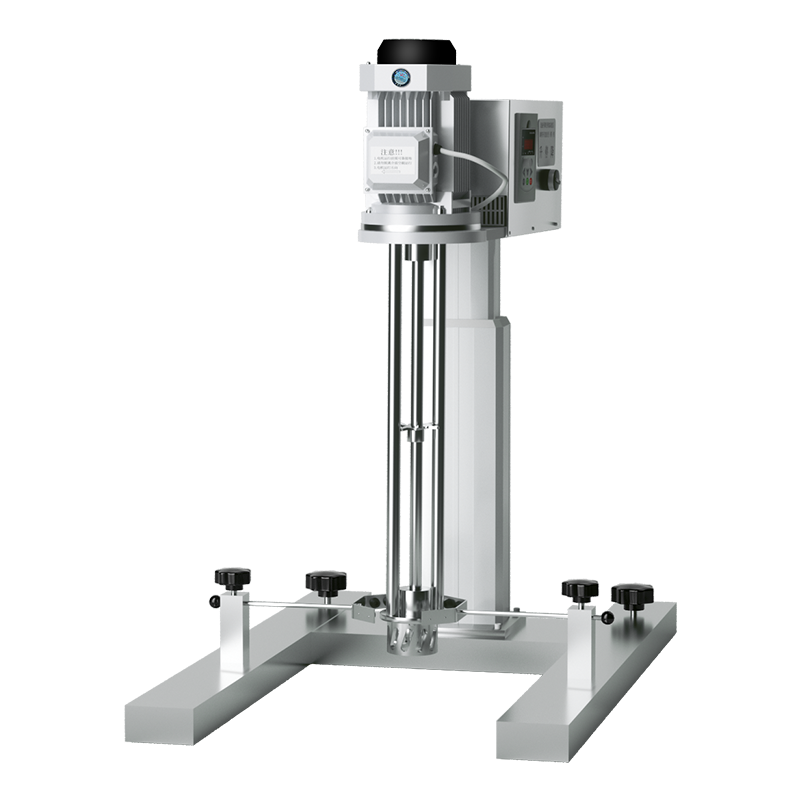

Electric lifting Emulsifier

Product Model:HR-2200DRH

Product Quote:面议

Related Products:

Application:

Laboratory electric lift emulsifier is a laboratory equipment designed for small laboratory experiments. Through the action of mechanical external force, the particle size of liquid and liquid, solid and liquid particles is narrowed to achieve the effect of refinement, homogenization, dispersion and emulsification, so as to form a stable dispersion system state, and can be equipped with a variety of products with different specifications of the work head . The sample is depolymerized, dispersed and homogenized, refined and sheared repeatedly for a certain period of time under the appropriate amount of emulsifier and mature technology to produce a stable emulsion. Application field: suitable for dispersing, emulsification and homogenization of product materials in industries such as biology, medicine, food, paint, ink, textile auxiliaries, cosmetics, lubricants, pesticides, etc.

Main Features:

● High efficiency, can quickly distribute one phase uniform material into another or more materials, achieve the effect of refinement, homogenization,

dispersion and emulsification, and the final product is stable and not easy to delaminate;

● High machining accuracy and long service life. The rotating stator is made of forging material and CNC machining center. The rotating stator gap

is small, the shear fineness is good, and the emulsification and dispersion efficiency is high. Optional cooling double-layer barrel, the equipment

can run for a long time and heat up Low, and can be automatically shut down according to the process timing emulsification time;

● Various modes, compact equipment structure, beautiful appearance of electric lifting equipment, labor-saving, no installation, according to the

viscosity of the material, select the appropriate single-layer/double-layer bucket, which can be used in different working conditions;

● Strong non-standard properties, various types of non-standard products can be customized, such as explosion-proof type, airtight type, manual

lifting type, etc. The material can be customized according to requirements SS304/SS316L/Hastelloy/Titanium Molybdenum Nickel alloy and other materials

. At the same time, different emulsification heads can be customized according to the viscosity of the material to meet the needs of laboratories

or small batches;

● 304 stainless steel case, fixed base.

| Technical Parameters: | |

|---|---|

| Model | HR-2200DRH |

| Motor type | Three-phase asynchronous moto |

| Power | 2200W |

| Capacity | 100L(water as example) |

| Speed(2P) | 0-3000r/min |

| Rotor stator | Long hole type (standard) / mesh type / claw type |

Lifting mode | Electri lifting |

Lifting Distanc | 500mm |

Exterior Dimensio | 750*620*1050mm |

Base Dimensio | 395*420mm |

Emulsification lengt | 700mm |

Emulsifying head off the ground size | 50-550mm |

Rotating stator classification:

Long hole type stator head: suitable for the rapid crushing of medium solid particles and the mixing of medium viscosity liquids, the long hole provides the largest area and good circulation for surface shearing.

Mesh stator head: suitable for low viscosity liquid mixing, its shear rate is the largest, most suitable for the preparation of emulsion and the process of crushing and dissolving small particles in liquid.

Claw-type stator head: The two-way suction method forms a two-way hyperbolic large circulating vortex in the container, which avoids the dead angle caused by the difficult suction of container materials, and makes the emulsification and homogenization more thorough.

Welcome to Shanghai Huxi Industry Co.,ltd

Welcome to Shanghai Huxi Industry Co.,ltd